Minimize Backlash at Higher Angles With Needle Bearing U Joints

High speeds can be problematic for joints fitted with plain friction u joint bearings, even if the transmitted torque is low.

Needle-Bearing universal joints are equipped with roller u joint bearings that reduce friction. These high-precision joints are built to maintain minimal backlash at higher angles for critical applications, such as robotics and instrumentation. Needle-bearing u joints deliver superior lifetime at continuous operations and high RPM at operating angles of up to 45°. They have the capability to be rebuilt when wear and tear occurs – a Belden exclusive.

Features:

- Minimizes and maintains near-zero torsional backlash

- Superior lifetime at continuous applications and high RPM (up to 6000)

- Operating angle up to 90° (45° per joint)

- Needle bearings lubricated for lifetime of the joint

- Boot covers are recommended in gaseous and abrasive environments

- Yoke material: fatigue-proof steel or stainless steel

- Cross material: high-grade alloy steel, hardened and precision ground

- Hub ends available with several standard bore configurations (plain bore, keyway, hex- and square bore)

- Optionally available Platings: Zink, Nickel, Cadmium, MoS2, Black Oxide

- Pin & block design with needle bearings available as well

- Telescoping Drive Shaft also available upon request

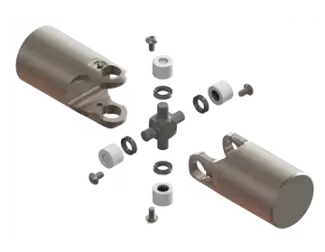

Needle Bearing Universal Joint

Needle-Bearing Joint - Exploded View