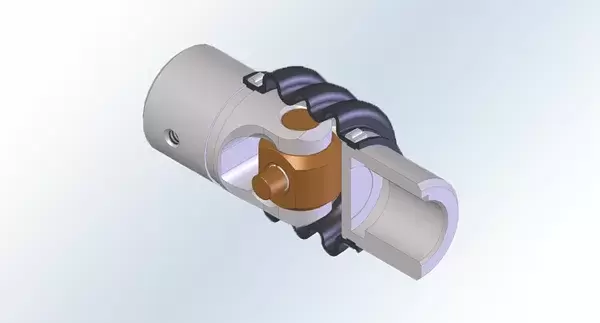

Due to outdoor exposure, the yokes of this 2” OD single universal joint were manufactured from corrosion-resistant 316L stainless steel. The pins & blocks were machined from to aluminum-bronze, a material that is highly suitable for friction reduction, in addition to its corrosion resistant properties. The hubs were customized with so called ‘blind bores’ as opposed to ‘through bores’, meaning they are only machined to a specified length, providing a “stop” and preventing the shaft from breaking thru to the center components. A black silicone grease-filled boot cover was added to deliver continuous lubrication to the the pins and block. The image shown above is a partially-cut model, exposing the aluminum-bronze pins & block.

For more information on Belden's custom universal joint solutions, visit https://www.beldenuniversal.com/products/custom-universal-joints.