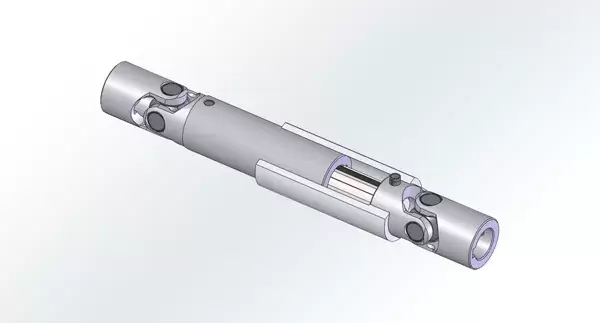

The customer's previously used product often suffered from worn-out spline shafts since the application required the shaft to extend and compress in operation. The drive shaft was also lacking proper lubrication, since the application did not allow space for a lubricant retaining boot. Belden’s new solution included a nylon cover, fixed on the short inbound yoke, sliding freely along the sleeve diameter. The spline shaft length is dimensioned so there is always a gap for lubricant under the cover, even at closed length. To further improve the spline shaft’s lifetime, it is nitride heat-treated for hardness and wear resistance. The Nylon cover on this illustration is partially cut open for a better view of the shaft’s components.

For more information on Belden's custom universal joint solutions, visit https://www.beldenuniversal.com/products/custom-universal-joints.